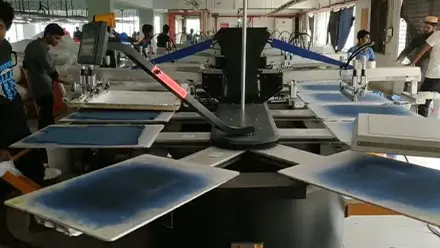

The Cnding H38 oval screen printing machine and digital printing machine hybrid system redefines intelligent manufacturing standards in the textile printing industry. As an innovative screen printing machine manufacturer, we integrate the craftsmanship of traditional screen printing with digital precision through a modular oval track design. The oval printing machine unit achieves 0.01mm registration accuracy for multi-material printing using screen printing materials like slurries, thick plates, and solvent-based inks. This makes it ideal for challenging 3D shoe print applications on athletic footwear. With pneumatic screen frame mounting and intelligent synchronized cleaning, the screen printing kit changes take just 3 minutes – a 90% efficiency improvement over conventional manual screen printing machines.

The digital unit features 12 Ricoh Gen5 printheads, embodying cutting-edge digital screen printing machine technology. It's 605×1200dpi resolution reproduces gradient transitions flawlessly, while four-color nano-pigment inks execute intricate screen printing designs beyond manual capabilities. Our proprietary negative pressure degassing system and climate control modules eliminate color bleeding in embroidery screen printing hybrid processes, overcoming limitations of traditional semi-automatic screen printing machines. It maintains a stable 450 pcs/hr output even on stretch fabrics like Lycra.

Enhanced with industrial-grade drying cabinet temperature management, the oval unit ensures rapid ink curing. The digital module’s automated printhead maintenance enables lights-out operation. Powered by an i7 processor and NeoStampa color software, this hybrid solution caters to automatic screen printing machine-level mass production and small-batch customization. It's a unique hybrid workflow that seamlessly integrates screen printing and embroidery processes, delivering an end-to-end solution for apparel/footwear brands. With expandable configurations (up to 30.87m length/78 stations), the H38 series drives the industry’s shift toward agile, digitalized manufacturing.

Oval Printing Machine Equipment Features

Precise registration with a 0.01mm tolerance.

Suitable for garment printing, supported applications include unique screen, slurry, flocking, pressing, water-based or solvent-based ink printing, thick plate, pull print, etc.

Driven by reliable servo motors, the independent precision positioning system ensures long, stable operation at low noise and low power consumption.

A printing experience driven by an AC motor with variable frequency, customers can rest assured of efficiency and stability.

An oval structure enables modular, customized systems, which are convenient for customer layouts with the addition of more workstations and printer heads with great ease.

Fast installation and removal of screen frames & full compatibility with all frame sizes

On-spot screen cleaning work without needing to remove the screen. It’s professional and operation works intelligently in synchronization with the printer heads.

Digital Printing Machine Equipment Features

Applying high-precision industrial-level Ricoh gen5 grayscale printhead

Printing speed up to 450 pcs/hr

Resolution up to 605*1200dpi

Printhead auto cleaning function to make printhead maintenance easier

Linear motor and metal raster increase printing speed, precision, and stability

Efficient ink degassing and negative pressure system guarantees stable ink supply